CHECK VALVE SWING DUCTILE IRON/ WCB DN40- DN600

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

- OKorder Service Pledge

- Quality Product

- Order Online Tracking

- Timely Delivery

- OKorder Financial Service

- Credit Rating

- Credit Services

- Credit Purchasing

Details

Standard or Nonstandard: | Standard | Structure: | Check | Pressure: | High Pressure |

Power: | Hydraulic | Material: | Casting | Temperature of Media: | High Temperature |

Media: | Water | Port Size: | Flanged | Place of Origin: | China (Mainland) |

Model Number: | CVE | Brand Name: | CMAX | Application: | General |

Design Standard: | BS EN 593 | Color: | bule/red/customized | Connection Ends: | BS EN 1092 PN 10/PN16 |

Temperature: | -29°~+425° | Port size: | NPS 2"-42" | Working Pressure: | PN10/PN16 |

Temperature Pressure: | 0℃ to 80℃ | Coating: | Fusion Bonded Epoxy | Operation type: | water |

Surface: | Powder coating/Acid pickling/Paint |

Packaging & Delivery

Packaging Details: Standard export package or as per your requirements

Delivery Detail: 25 days from date of order

Technical Date | Material Specification | ||

Nominal Diameter | DN40-DN1000 | Valve Body | Cast Iron or Ductile Iron |

Nominal Pressure | PN10/PN16 |

Valve Disc | Cast Iron or Ductile Iron or Stainless Steel |

Operation Temperature | -40°C~225°C | ||

Flange Driling Standard | EN 1902-2 PN10/16 | Seal Material | EPDM OR NBR |

Suface Treatment | Painting |

Valve Spring |

Stainless Steel |

- Q:What is the material of H41W-16's check valve?

- According to: JB/T 308-2004 "valve type programming method"H check valve4 flange connection1 lift through straight through valve passageW sealing cover for body material16 nominal pressure PN16When the nominal pressure is less than or equal to PN16, do not mark the material code of the valve body, the valve body material is gray iron

- Q:Why should the check pipe be added to the chilled water pipe of the air conditioning unit?

- Check valves are usually installed at the exit of a group of pumps. I have not heard of the installation of check valves at the location of the air conditioning unit.The function of the check valve is to prevent backflow. Prevent backflow of water in water pipe and knock out impeller of water pump.

- Q:Circulating water check valve, I want to ask is not greater than DN600, you can use HBH747H hydraulic butterfly valve closed butterfly valve, less than DN600 of HD43X slow butterfly butterfly check valve, what does hydraulic check mean? Need hydraulic?

- Greater than DN600, you can use HBH747H hydraulic butterfly butterfly valve closed, less than DN600 with HD43X slow butterfly butterfly check valveThis is the usual selection, not necessary, there is no provision, but this choice is not wrong. There are, of course, other types of check valves.The hydraulic check valve is hydraulic, and the Baidu library contains instructions for the HB series and the HD series hydraulic check valves

- Q:Can the exhaust air outside the wall be fitted without a check valve?

- What you are talking about is the backflow blower of the exhaust fan. This is usually installed. It is a method of preventing the air stream from returning under the condition that the fan stops running. If your fan is only a common wall exhaust, you can not install it, but if it is a discharge of air pollution or dilution of dangerous air flow, then advise you to install it as well.

- Q:What's the difference between the cut-off, check, check, and stop valves three? Better picture,

- Stop check valve: when the handwheel is rotated so that the valve stem rises, the disc does not rise together, but only the valve clack is released.

- Q:What is the HH44X-16 H of the double acting slow closing check valve? Can you explain it in detail?

- 2, micro resistance, slow closing check valve, also known as check valve, its role is to prevent the medium back in the pipeline. The opening and closing parts depend on the flow of the medium and the power is turned on or off by itself. The valve that prevents the backflow of the medium is called a check valve. Check valves belong to the automatic valve, mainly used for one-way flow of media channels, allowing only medium to flow in one direction, to prevent accidents. Suitable for cleaning medium, not suitable for medium containing solid particles and viscosity.

- Q:Are check and check valves the same kind of thing?

- Yes, that's right. Ha-ha。 My friend needs an anti - stop valve to find me. I have one for sale here.

- Q:How to install the check valve?

- Check valve [1] called one-way valve or check valve, its role is to prevent the media back in the pipeline, a swing check valve: Valve swing check valve cylindrical disk-shaped, around the seat of the shaft for rotation channel, because the valve channel into a streamlined, flow valve smaller than the lift check, for large caliber occasions in low flow and no flow frequently changes, but not for the pulsating flow, the sealing performance is less than lift. Swing check valve is divided into single, double, and most types of three, the three forms mainly by the valve bore points, the purpose is to prevent the media to stop flow or reverse flow, weakening the hydraulic impact. Two. Lift check valves: check valves slide along the vertical centerline of the valve body. The lift check valves can only be installed on the horizontal pipe. The disc can be used in the high pressure small bore check valve. The valve body of the lift check valve is the same as the cut-off valve (which can be used with the stop valve), so it has a large coefficient of fluid resistance. The structure is similar to the cut-off valve, the valve body and the disc are the same as the cut-off valve. The lower part of the upper valve and the valve cover processing guide sleeve, the valve in the valve lift free guide simple simple light driven, when the medium downstream, the valve thrust open by the media, when the media stopped flow, the valve by the self vertical landing on the seat, preventing the media from the upstream effect. Straight through lift check valve direction of medium inlet and outlet channel direction perpendicular to the seat; vertical lift check valve, the media import and export channel in the direction of the same direction with the valve seat, the flow resistance is smaller than the straight through.

- Q:Our unit pump outlet check valve installed in the vertical pipe, the use of the valve to stop the valve is more serious impact, is not installed, the valve should be how to install it?

- Check valves shall be installed on the vertical pipe. Select a model, such as a slow closing check valve (water hammer) or a spring check valve.

- Q:Fire hood fire check valve okay?

- 1, the new product role2, the role of soot exhauster smoke exhaust fumes sent to the public flue gas pipeline, with the smoke fumes from the flue gas flow into the room to ensure that the quality of the domestic air environment, home health3, fire valve temperature control device and block check plate up to prevent the flame through public exhaust pipe series.4, the specific selection to check, see products through fire products, testing, assessment, no certificate, and price

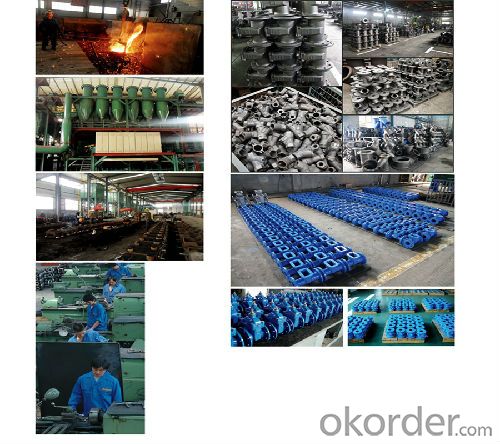

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Similar products

New products

Hot products

Hot Searches

Related keywords

You Might Also Like