Black Anodized aluminium plates 5083 2-20mm

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 360 m.t./month

- OKorder Service Pledge

- Quality Product

- Order Online Tracking

- Timely Delivery

- OKorder Financial Service

- Credit Rating

- Credit Services

- Credit Purchasing

Item specifice

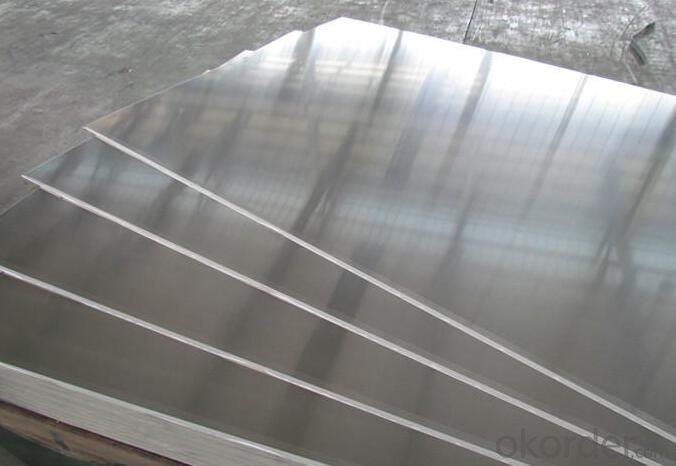

Mill Finish Black Anodized Aluminum Sheet

1. Commodity: 5083 Aluminium Plain Sheet for Marine Use

2. Alloy No.: 5083

3. Size: Thickness: 2-20mm (Tolorance±0.02mm) Width:200-1600mm(Tolorance±1mm) Length:500-1500mm(Tolorance±1mm)

4.Application: air plane, refrigerators ,audio equipment, ships building ect

5.Month Capacity: 5000MT/Month

6. Specification:

1. | Item | Aluminum plate/ Aluminum sheet,aluminium plate price, aluminium chequer plate,aluminium sheet,aluminium sheet price | |

2. | Standard | ATSTM,AISI,JIS,EN,GB | |

3. | Alloy | 5083 | |

4. | Specifications | Thickness | 0.5mm~200mm |

Width | 100mm~3000mm | ||

Length | 2m,3m,5.8m,6m,or as required | ||

6. | Surface | Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc. | |

7. | Price Term | Ex-work, FOB, CIF , CFR, etc. | |

8. | Payment Term | T/T, L/C, Western Union, etc. | |

9. | Delivery Time | According to order’s quantity. | |

10. | Package | Export standard package: bundled wooden box, suit for all kinds of transport, or be required. | |

11. | MOQ | 10000kg | |

12. | Export to | Asia, Europe, Africa and South America | |

13. | Application | air plane, ship building, refrigators and other industry products | |

Packaging detail: First, plastic cloth; Second, Pearl Wool ; Third, wooden cases with dry agent ,without fumigation, wooden pallets

Delivery detail: Within 25days

FAQ:

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

- Q:Does it make any difference shiny side up, shiny side down when it comes to cooking with aluminum foil?

- The shiny side is slightly better reflector of heat. Face that side of the foil in the appropriate direction. To keep things cold, put the shiny side on the outside -- that will reflect incoming heat. To keep things warm, face the shiny side inward toward the hot food -- to reflect the heat that is trying to escape back into the food. Note that people often bake potatoes with the shiny side out -- that is because it makes for a better (prettier) presentation. In reality, baking them that way reflects the incoming heat on the outside, slightly slowing the cooking process. Of course, in reality, which side of the foil faces where makes little difference. It does make for lively conversation, though.

- Q:What kind of paint would you like to paint on the aluminum plate?

- Paint on the aluminum plate should be painted nitrocellulose or polyester paint.Is the aluminum plate with a thickness of more than 0.2mm to 500mm, 200mm width, length less than 16m aluminum material called aluminum plate or aluminum sheet, aluminum is below 0.2mm, 200mm within the width of the row material or bar (of course, with the progress of the large equipment, the width can be 600mm row material also more). Aluminum sheet refers to the rectangular plate made of aluminium ingot rolled and divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, middle thick aluminum plate and pattern aluminum plate.Nitrocellulose lacquer is a common paint for woodwork and decoration. The main film forming material is mainly to nitrocellulose lacquer, with alkyd resin, rosin modified resin, acrylic resin, amino resin and other resin composed of hard and soft.Polyester paint, also called unsaturated polyester paint, is a kind of multi component paint, it is a kind of thick paint made of polyester resin as the main film forming material. Polyester paint film fullness, thick hard surface. Polyester paint also has varnish varieties, called polyester varnish. Polyester paint needs to be solidified during construction, and the proportion of these curing agents takes up 1/3 of the total paint. These curing agents, also known as curing agents, are mainly composed of TDI (toluene diisocyanate, /toluenediisocyanate). These free TDI will turn yellow, not only to make furniture paint yellow, but also will make the adjacent wall yellow, this is a major shortcoming of polyester paint.

- Q:I have to repair a cracked aluminum engine block. What alumunum epoxy should I use?

- elmers glue! Lol. I believe you can have it welded. That will last for a while.or until you can get another one.

- Q:i want to a material which is similar in properties like aluminium which has similar casting properties and easily available.

- brass

- Q:What are the colors of iron sheet and aluminum sheet?

- silver white

- Q:I broke the swing-arm of a cut-off saw, need to know how to weld it back. I have a stick welder and can weld steel, but have never messed with cast aluminum.

- If it has a silvery-grey appearance and is very light, than it is probably aluminum, especially if you did a spark test and nothing happened(ruling out magnesium, which is unlikely for a random part anyway). Aluminum is alot lighter than steel, if you are holding it you would beable to tell. Magnesium is lighter than aluminum, but will give of red spark when touched with a grinder or shavings are lit. Cast aluminum can be welded with a wire spool gun, any certified aluminum shop(and most welding shops in general) would have one. It can also be Tig welded which would take longer but may yield a better result. *** Do not preheat the aluminum that hot, never preheat it more than 150°F, at 300°F you will start to degrade the aluminum, especially if it is an alloy. Aluminum melts at 1220°F but with preheat it would be possible to exceed that(especially with a spool gun). Do not do multipass beads without allowing it to cool. You will need to clean the oxide off the surface with a stainless steel brush or acid, normal steel will leave impurities that will affect you welding.

- Q:does anyone know how aluminum recycling works in term of redox reaction ( oxidizing, reduced, oxidizing agent, reducing agent?). how is that relate to the process of electrochemistry?

- Aluminum recycling is done by just melting the cans back into molten metal. There are reactions, but those deal with the impurities, not the aluminum. See the reference.

- Q:What is the most efficient and low cost method for welding 1mm-3mm aluminum sheet?,What's new?

- If the cost is low, or belongs to the welding; and to stress the process of words, or to inert gas welding (TIG or MIG), and can use tungsten arc alternating current arc welding or tungsten arc argon arc welding.

- Q:im making a presentation and once i read through it it feels like its leading up to something but then goes flat. any ideas. my project ' steel cars compared to aluminium'

- Aluminium is extremely flammable. We use it in thermite welding and as solid rocket fuel. The Emperor Napoleon carried* an aluminium fork while the lower royalty had to make do with gold forks. *In those days people carried their table wear around with them same as we carry our car keys.

- Q:What's the maximum size of 3 mm thick aluminum sheet?

- First look at tolerance taggingIf there is no tolerance, see the accuracy level of the workpiece and check the tolerance listA 3-4 mm deviation is acceptable if the magnitude is not noted and is of no importanceThat is, the 34mm can also be used if lower precision sizes can be addedOnly board class is generally down bias, there is very little difference

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Similar products

New products

Hot products

Related keywords

You Might Also Like